Top Load:

The top-load, or discharge terminal, has two functions. One, as the name suggests, is to act as the output terminal for the streamer discharges, and the other is as a capacitive load for the secondary coil.

The shape and size of the terminal greatly affects the performance of a Tesla Coil. As already mentioned, it behaves as a capacitor (connected between the top of the secondary and using air as a dielectric to ground). Its value determins the resonant frequency of the secondary coil circuit. Changing its size and shape will change the systems operating frequency, and as we are primarily concerned with achieving resonance between the primary and secondary coils, any change to this frequency requires re-tuning of the primary circuit.

The top-load, being a capacitor, stores energy and then releases it as a streamer. A large top-load can store a lot of energy, allowing the voltage to build, and requires a coil with sufficient power to exceed this amount of energy in order to have it break down the air and create a spark. A low powered coil with a large top-load may be tuned to resonance and still not produce any visible output. On the other hand, a powerfull coil, tuned to match a small top-load, will produce lots of small streamers instead of a few really long ones. The more power the coil can process, the larger the top-load needs to be.

In all the shops I've ever been

in, I have not yet seen any large metal doughnut-shaped items for

sale! I guess I'll just have to make one!

Construction:

Aluminium ducting is ideal for making

toroids and is available in most DIY stores as kitchen cooker extraction-hood

ducting. It is usually only available in 4 inch diameter.

For larger sizes, check out CCL

Veloduct Ltd and look for 'Tecflex 500'.

There are as many ways

to make your discharge terminal as there are coilers but the materials

I have chosen to use are 4 inch aluminium ducting, pie dishes and some

aluminium tape (duct tape).

![[aluminium ducting]](graphics/ducting.jpg)

![[pie dishes]](graphics/pie_dishes.jpg)

![[aluminium tape]](graphics/al_tape.jpg)

Form the ducting into a loop and tape the ends together, to form a ring. Make the diameter such that the pie dishes are a tight fit when brought together from either side of the ring.

![[torus]](graphics/toroid1.jpg)

With the addition of some bolts near to the edge of the dishes, you can tighten the two centre halves together to complete the top-load.

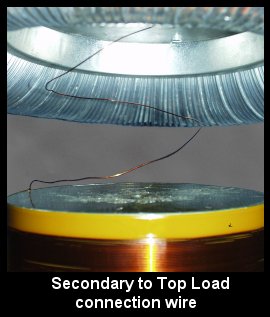

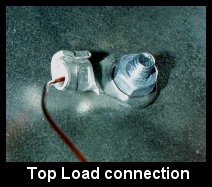

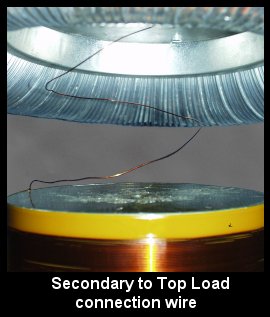

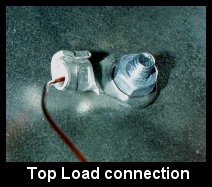

The secondary wire is brought to the topload in a loose spiral, circling the support.

The wire end is cleaned of enamel and terminated with a crimp eyelet, which is then bolted fingertight to the underside of the toroid.

Top Load:

The top-load, or discharge terminal, has two functions. One, as the name suggests, is to act as the output terminal for the streamer discharges, and the other is as a capacitive load for the secondary coil.

The shape and size of the terminal greatly affects the performance of a Tesla Coil. As already mentioned, it behaves as a capacitor (connected between the top of the secondary and using air as a dielectric to ground). Its value determins the resonant frequency of the secondary coil circuit. Changing its size and shape will change the systems operating frequency, and as we are primarily concerned with achieving resonance between the primary and secondary coils, any change to this frequency requires re-tuning of the primary circuit.

The top-load, being a capacitor, stores energy and then releases it as a streamer. A large top-load can store a lot of energy, allowing the voltage to build, and requires a coil with sufficient power to exceed this amount of energy in order to have it break down the air and create a spark. A low powered coil with a large top-load may be tuned to resonance and still not produce any visible output. On the other hand, a powerfull coil, tuned to match a small top-load, will produce lots of small streamers instead of a few really long ones. The more power the coil can process, the larger the top-load needs to be.

In all the shops I've ever been

in, I have not yet seen any large metal doughnut-shaped items for

sale! I guess I'll just have to make one!

Construction:

Aluminium ducting is ideal for making toroids and is available in most DIY stores as kitchen cooker extraction-hood ducting. It is usually only available in 4 inch diameter.

For larger sizes, check out CCL Veloduct Ltd and look for 'Tecflex 500'.

![[aluminium ducting]](graphics/ducting.jpg)

![[pie dishes]](graphics/pie_dishes.jpg)

![[aluminium tape]](graphics/al_tape.jpg)

![[torus]](graphics/toroid1.jpg)