First light was achieved on the 26th February, 2000.

All the major components were ready except for the primary capacitor. The original design was a poly-plate cap but because the amount of work involved in making one is enormous, a short-cut was taken and an MMC was built instead. (I hope to finish the poly cap some time).

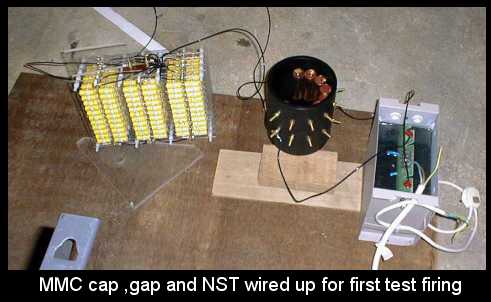

The support frame for the coil was not quite finnished either, so a quick setup was thrown together in the garage. The interconnecting wires were much longer and thinner than a primary tank circuit should be but were perfectly acceptable for a first attempt; this gave plenty of scope for future improvements! We used a 4 foot copper plated rod driven into the lawn for our RF ground.

The initial primary tap point we used was within 2 turns of propper tune and was a good start to the testing, thanks to the 'WinTesla' program. We soon created lots of small violet streamers from all over the toroid but could only wind the variac up about half way before the coil was upstaged by loud flashes from the cap! The wiring in the MMC was suffering from clearance problems and sparks were jumping accross some of the connections. I thought the cap was going to need a complete redesign before more testing could continue. We also realised that the discharge terminal was way too small for the power we had. While Mike (Tucknott) popped home to get some of his toroids I set about rewiring the MMC.

With the extra top-load in place and the MMC problem fixed, we were able to tune the coil to give bright white streamers, hitting both garage walls, with some ground strikes that measured 55 inches!! The primary was now tapped at about turn 8 of the available 9.

It was very very loud! Ear defenders are essential when running a coil in a confined space.

We experienced arcing and burning on the connection board of the NST, between the 'Earth' and 'Live' tracks, but this stopped when we connected the case of the NST to RF ground (forgot to do it before!).

We experimented with raising and lowering the height of the primary with respect to the secondary, to change the coupling between them. All changes decreased the streamer length. We must have been spot on to start with.

My digital camera has no manual overide settings and so I could not get any photos of the coil running in the dark (or me in the garden with a fluorescent tube pretending to be Luke Skywalker!! ;-) ), and the results with the lights on would have been poor. On one attempt the camera got confused, while trying to write data to its memory, and lost a shot. This was at a distance of about 7 feet from the coil.

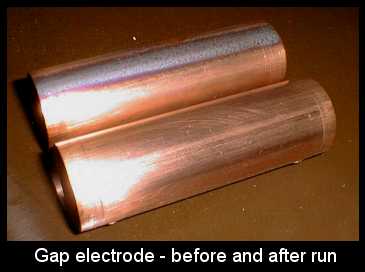

Throughout the short test firings (10 to 40 seconds duration), the gap electrodes remained reasonably cool, and when we ran the coil at full power for a couple of minutes it still did not get too hot. At the end of a 4 minute run, we started to see the performance drop rapidly as the gap got really hot. The black polyethylene tube used in the gap remained intact and showed no signs of any problems; we had thought that the carbon used for the colouring agent might cause the tube to flashover or heat up. Not sure how it would perform as a secondary form though.

I need to build the cooling fan box for the gap before any more long runs, and sort the support out so I can shorten the primary tank wiring.