Wire

Types and Sizes

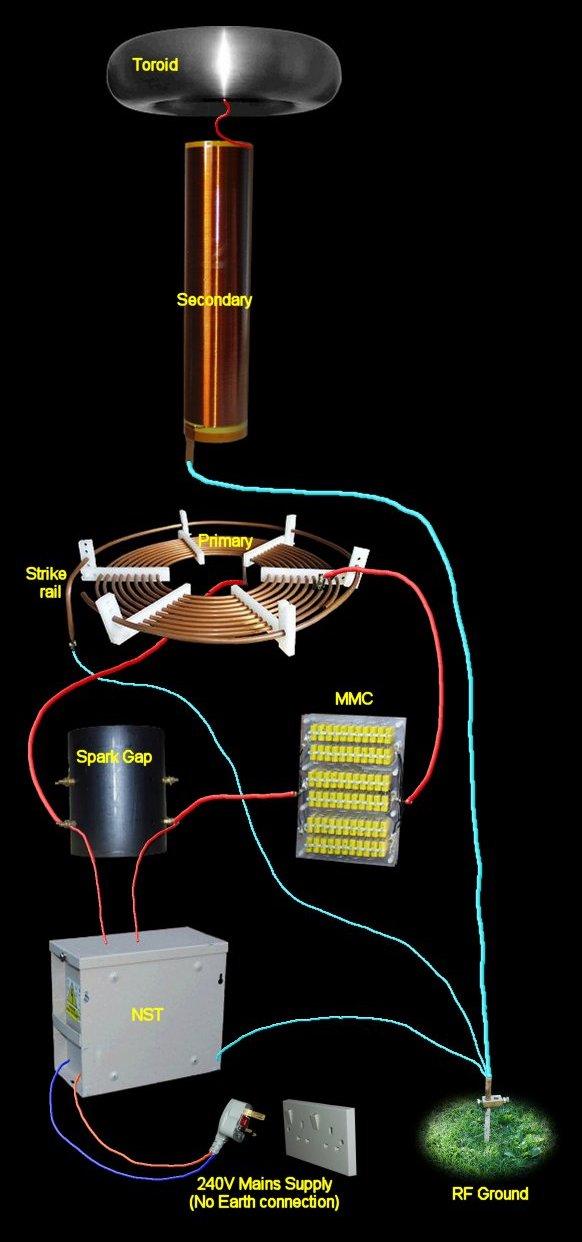

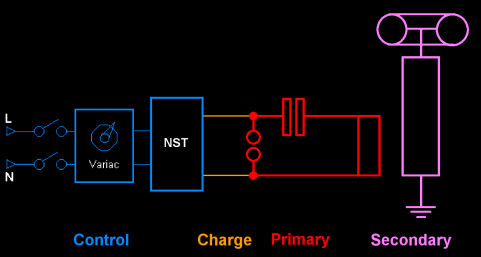

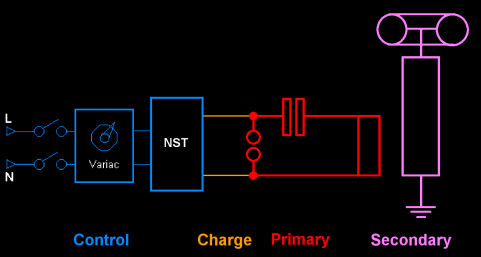

The

type and size of wire used in a Tesla Coil system should be chosen to

match the specific needs of each part of the circuit. The system can

be split into four sections:

The

Control section uses correctly rated mains cable.

Typical cables are 'E' & 'D' (see below).

The

Charge section is high voltage and low current.

Suitable cables are 'A' & 'B'.

The

Primary section is high voltage and high current.

Suitable cable is 'F'.

The

Secondary section. The RF ground connection is low voltage

and high current.

Suitable cable is 'F'.

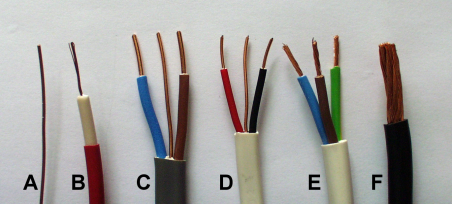

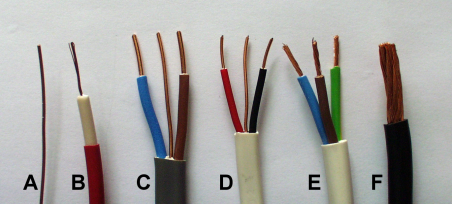

| A |

bare

single strand (1.0 sq mm) |

| B |

EHT

cable 25KVDC |

| C |

twin

and earth (2.5 sq mm) |

| D |

twin

and earth (1.0 sq mm) |

| E |

3

core flex 16A (1.5 sq mm) |

| F |

car

battery lead (overall diameter 8mm) |

Voltage:

Because

of the high voltages found in a Charge & Primary sections

it seems natural to look for cable with high voltage ratings, such as

neon sign cable, medical X-ray equipment cable & car engine spark

plug leads. The first two would be fine for connecting the NST to the

spark gap but the spark plug leads are useless (too high a resistance).

However, you don't need to spend lots of money on fancy HV cable because

all sorts of ordinary wire would work too. All you need to do is think

about insulation.

Insulation:

For

a circuit to work you need wires to conduct the electricity between

the components. A bare piece of wire will do this perfectly but you

now have the problem of wires accidentally touching and shorting out.

Depending on the voltage being used you may also have the added risk

of electrocution! Insulation is used to solve both these problems but

for high voltages, like in a Tesla Coil, the cost of suitably insulated

cable is high.

The

solution is to use ordinary low voltage cable, or bare wire, and use

air as your insulatior (just like the big boys do with the National

Power Grid!). All you need to do is to secure the wires in such a way

that they cannot short against anything conductive and are at a safe

distance from operator's hands.

Current:

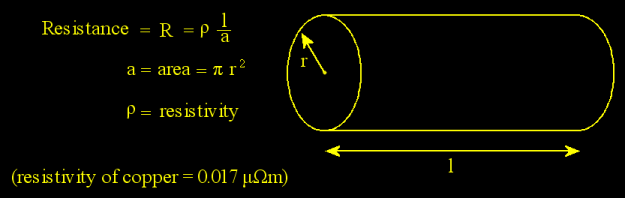

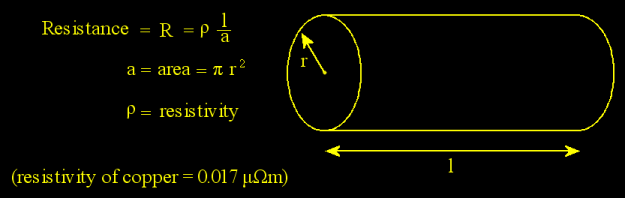

All

conductors, except for 'superconductors', resist the flow of current

through them. The value of this resistance is determined by the material

used for the conductor and by its size.

As the cross-sectional area 'a'

gets smaller, or the length of the wire 'l'

gets longer, the resistance 'R'

increases.The higher the resistance the more electrical energy is used

just in fighting against it. This causes power to be lost in the form

of heat.

- Example:

The

heating element in an electric kettle uses wire with a high

resistance to generate heat. The wire connecting the kettle

to the wall socket has a very low resistance, to avoid

heating.

|

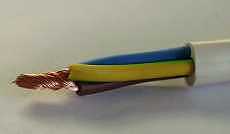

High

current:

High current connections in the 'Primary' section

require thick cables to keep resistance values to a minimum. Cables

'C', 'D' and 'E' can be used for high current Tesla

Coil use but should be treated as single conductors (see below). Cable

'F' is good for high currents too but not as easy to find in

the shops.

|

Conductors

joined together at both ends for high current use

|

|

Low

Current:

The low current 'Charge' section can use thin cable without any

measurable loss of power. Cables 'A' and 'B' are fine.

By removing the outermost layer of insulation from cables 'C',

'D' and 'E' the individual wires are perfect too (see

below).

|

|

Conductors

separated for low current use

|